News from NAMM: Custom Headphones Minus the Goo

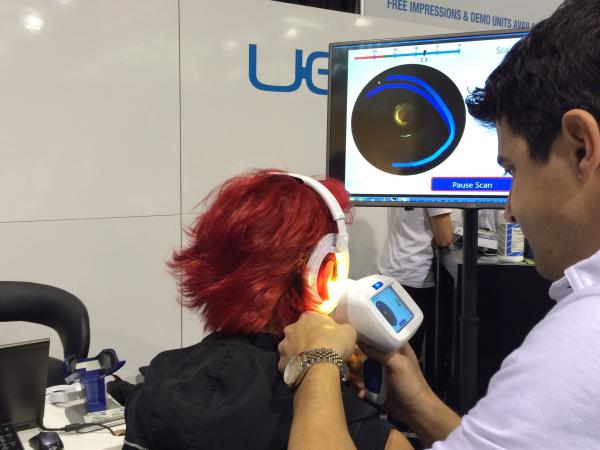

In-ear headphone fans rejoice: the custom monitor is now available without the goo. This week at the NAMM show in Anaheim, Ultimate Ears showed off its partnership with United Sciences, which has come up with a way to use a laser 3D scanner to take a virtual “impression” of your ear canal. It’s all very sci-fi, and could change the entire face of headphones as we know it. How does it work?

First of all, for the uninitiated, the process of getting ear impressions has been largely unchanged for quite some time. Basically, you first go to see an audiologist who cleans your ears and puts a bit of cotton or foam deep in your canal to protect your eardrum. She then injects your ear canal using a syringe with a cool silicone goo. You sit, biting a piece of foam while this goo hardens, and try not to drool too much. After ten minutes or so, the goo is hardened, the impressions are gently wiggled loose, and then they are sent off to be either 3D scanned or made into a mould for your future custom monitors. If you want to see more about that process, and how Ultimate Ears makes the headphones from this point on, check out my previous post about the facilities tour I recently took.

So, as you can see, the silicone method is kinda awkward, and requires a professional to complete. This means getting your schedule to coincide with an audiologist, and getting to an office (or, if you have the means, paying one to come to you.) More or less, it’s a bit of a nuisance, and generally isn’t something that can be done spur of the moment.

The in-ear 3D scanner would change all of that. According to United Sciences’ CEO Samuel B. Kellett Jr., these new scanners are easy enough to use that the need for an audiologist in the headphone fitting process would be obsolete. He claims that even retail associates could be trained to use the scanner, and so custom headphones could be measured, designed, and ordered at a retail point of purchase.

And he’s thinking bigger than just the current pro monitor world. United Sciences has also partnered with Harman, and plans to expand. Imagine going to the Apple store, picking up the latest iPhone, and getting scanned for compatible headphones that fit your ear canal perfectly. High quality models would even adjust the position and angle of the drivers to best optimize the direction in which the sound waves hit your ear. Less expensive designs could be printed with a 3D printer on the spot for you to take home within the hour. The folks at Comply should feel a cold chill down their spine right about now.

Just think: a world without fiddling through endless baggies of silicone tips to get the correct fit. And if that’s not enough, Kellett says that the accuracy of the scan is so good, that headphones and hearing aids could be fitted with EEG sensors, allowing for brainwave feedback to control the device. Yeah. You read the correctly. He says eventually you could think “answer” and gently nod rather than press a button to answer a phone call from your headphones. But that’s all a decent ways off.

For now, expect to see ear canal scanners at retail stores near you in the not too distant future. Just like you can get your ears pierced at a mall kiosk, soon you’ll be able to order your custom monitors, grab an Auntie Anne’s pretzel, and have your new in-ears before you can finish licking the cinnamon from your fingertips. Welcome to the future, guys.