Lab Developments Promise True Flat-Panel Displays

Nanotubes are a laboratory curiosity that arose from the discovery of fullerenes in 1985. Fullerenes are spherical carbon molecules, sometimes called "bucky balls" after author, architect, and theorist Buckminster Fuller because their chemical structure echoes his famous geodesic domes. These molecules can be used to construct nanotubes, which resemble microscopic rubber hoses and are used as probes for extremely sensitive scanning microscopes. In addition, they have been proposed as insulators for wires with conductors only one molecule thick, which might be used as "leads" into very small microchips, for example. But until last week, nanotubes hadn't found their way into many commercially viable applications.

Researchers at SUNY might have changed all that. Ren and his associates have been able to grow nanotubes in tightly spaced rows on flat sheets of glass only one millimeter thick. The nanotubes emit electrons when they are electrically stimulated, which means that each picture element (or pixel) on a screen could incorporate its own "electron gun." This would yield tremendous savings in weight and energy over traditional CRT displays, in which three electron guns (one for each primary color) constantly scan the entire surface of a picture tube to create an image.

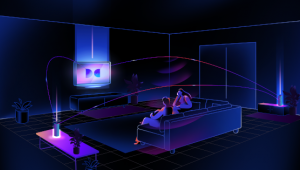

An integrated structure of glass, phosphor, and nanotubes could be connected to some sort of lattice-type driver circuitry, resulting in a lightweight, high-brightness/high-resolution screen that hangs on a wall like a mirror. Of course, there are many expensive obstacles to overcome between these laboratory developments and a commercial device, but Ren is convinced that his nanotubes-on-glass technique will work for video displays.

"Because each pixel is an electron source, there is no need for scanning and therefore no need for the distance between the electron source and the screen," Ren says. "Our nanotubes are beautifully aligned, they grow at relatively low temperatures, and they grow on glass. These lower-temperature growth conditions are suitable for electron emission applications, such as cold-cathode flat-panel displays."

Currently, gas-plasma and liquid-crystal displays are the closest things to true flat panels on the market. However, LCDs lack brightness and exhibit poor resolution when viewed off-axis. Plasma displays can be quite bright and offer excellent detail, but they must be at least a few inches thick to accommodate a volume of gas, which stimulates phosphors to glow by emitting ultraviolet light when it is ionized. In addition, prices for plasma displays are similar to upper-end direct-view and rear-projector technologies.

Ren and his team claim to have grown well-aligned, mass-scale nanotubes on glass at temperatures as low as 650°C (1202°F)---below the melting point of glass---by using ammonia as a catalyst. Their work was reported in the journal Science.