Blades of Glory

One of the primary principles under investigation is the concept of a "single apparent source," which strives to create the illusion that all frequencies are emanating from a single location rather than different locations as with the drivers in a conventional speaker. Toward this end, two pairs of identical woofers are side-mounted in a back-to-back configuration with a single, front-firing Uni-Q coincident midrange/tweeter located symmetrically between them.

One of the primary principles under investigation is the concept of a "single apparent source," which strives to create the illusion that all frequencies are emanating from a single location rather than different locations as with the drivers in a conventional speaker. Toward this end, two pairs of identical woofers are side-mounted in a back-to-back configuration with a single, front-firing Uni-Q coincident midrange/tweeter located symmetrically between them.

The 10-inch woofers in each opposing pair are mechanically coupled to cancel the forces between them and thus reduce unwanted cabinet vibrations, while the Uni-Q midrange/tweeter is decoupled from the cabinet using vibration-isolation techniques. Acoustically absorbent material is packed inside the cabinet to diminish the effects of resonant modes, and carefully placed internal bracing further reduces enclosure vibration.

Of course, every 3-way speaker needs a crossover, which KEF decided to place outside of the cabinet. The circuitry is hand-wired with air-core inductors and plastic-film capacitors that are said to exhibit extremely high resolution for reproducing fine sonic details.

For the Concept Blade, KEF's Uni-Q coincident midrange/tweeter enters its 10th generation. KEF engineers have determined that the optimal shape of the 1-inch tweeter dome is an ovoid—like the end of an egg—overlaid on top of a spherical cap, forming a somewhat triangular cross section between the two surfaces. The entire dome is made of titanium because of its exceptional stiffness and light weight. A radial-rib waveguide tames the characteristic resonances that crop up when a compression driver is placed in the throat of a horn or, in this case, a midrange cone.

That 4-inch cone is made of a super-stiff and ultra-light liquid-crystal polymer with radial ribs on the rear surface, which raises the cone's resonant frequencies well above its operating range. Also, the 3-inch voice coil is attached to the cone at one of its resonance-node locations—a location that does not move during resonance—to even out the driver's frequency response.

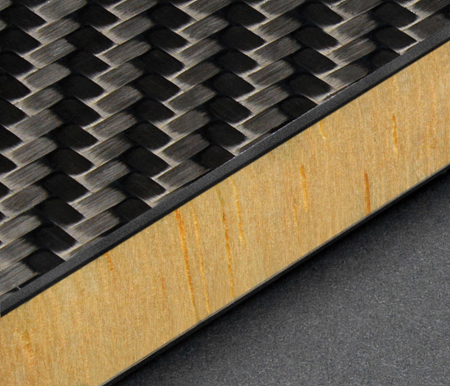

The enclosure is made of a resin-impregnated, woven carbon-fiber material over a balsa-wood core. This composite is used in airplanes, professional surfboards, and some ultra-high-performance cars because if its rigidity and light weight. The parabolic curvature of the cabinet enhances its rigidity even further—when combined with the other measures to prevent unwanted vibrations, this lets you hear the sound of the drivers by themselves with no contributions from any other part of the speaker.

The KEF acoustic-research team started with a completely blank slate—no preconceptions, no aesthetic restrictions, no reliance on existing components. After three years of advanced computer modeling, laser-vibrometric analysis, and extensive listening, the Concept Blade is said to produce an extraordinarily pure and open sound because all elements of the system were conceived to perform as a single, coherent unit.

I hope to hear these marvels some day, but since they aren't being offered for sale, that day will have to wait until I have the opportunity to visit the KEF facilities in Kent, England. Meanwhile, perhaps the lessons learned with the Concept Blade will be applied to speakers we can actually buy. One can always hope...