Let There Be Light: Larry Hornbeck, DLP Inventor

S&V: How did the idea for the digital micromirror device (DMD) come about? Was there a Eureka moment?

S&V: How did the idea for the digital micromirror device (DMD) come about? Was there a Eureka moment?

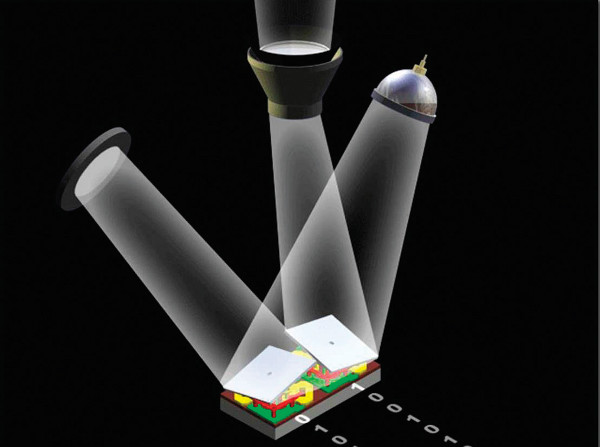

Larry Hornbeck: The DMD is a simple concept. When a mirror flips ON, a bright spot of light is created at the projection screen. When a mirror flips OFF, the spot goes dark. Flip 8 million DMD micromirrors at rates up to 10,000 times a second and incredible imagery is created on a movie screen. It seems that a concept that simple should have a Eureka moment and, indeed, according to folklore there are two versions of my Eureka moment:

1) I was driving to work one morning in my 1977 Chevy pickup and saw a flash of light from a glass door as it was suddenly opened and closed.

2) I was in a football stadium where fans were flipping flash cards.

Neither version is true!

In reality, the idea for DMDs came about along an evolutionary path that began in TI’s Central Research Laboratories in 1977 where I and a small team began the development of “deformable mirrors” to manipulate light in an analog fashion. But the analog technology consistently fell short of expectations. It was not until 1987 that I invented the DMD, the breakthrough technology that would become known as the DLP chips.

S&V: The concept of millions of individually controlled micromirrors seems so outlandish. Was there a specific business or scientific “problem” or obstacle you were trying to overcome?

LH: Yes. In the mid-1980s we were intrigued with the possibility that a light modulator array of analog micromirrors integrated on a silicon chip could bring superior performance to digital printing technology. By 1986, I had developed and patented a technique for building analog micromirrors in a standard semiconductor fab. However, the light uniformity was poor and drifted with time.

In 1987, with no other alternative in sight, I began using the micromirrors as simple on/off optical switches and implemented pulse-width modulation techniques to generate a digital image. Soon I filed a patent application for this breakthrough light modulator technology.

Although less than 10,000 digital micromirrors would be required for the digital printing application, by 1990 [we] could envisage DMD chips with millions of digital micromirrors for applications including digital projection and high-definition television!

In 1991, TI formed a corporate-level venture project to commercialize DMD technology and the rest is history.

S&V: What was the toughest barrier you had to overcome in bringing the DMD technology to fruition? Where were the struggles?

LH: I had to overcome many technical hurdles that had plagued researchers for years as they attempted to develop microdisplays as projection display alternatives to the cathode-ray tube (CRT).

The DMD brought some unique hurdles. For example, how do you reliably flip millions of digital micromirrors for trillions of cycles? Patented innovations in chip manufacturing and packaging are the answer to that question.

Looking back on my experience over the course of nearly 40 years, I can tell you that if you want to create a game-changing technology, then you have to work for a company like TI and a team of wonderful engineers that gives its people the opportunity to deploy their passion and creativity and push the boundaries of the impossible.

From the beginning, TI provided the tools and resources to develop the technology through a number of fundamental transformations before it was ready for full-scale commercialization—from hybrid manufacturing to monolithic integration on silicon, from analog to digital operation, and from the initial applications of optical processing and later digital printing, to the DLP Cinema display application for which it is well known today!

S&V: How long did it take to develop a working DMD prototype? Had TI ever been involved in projection/display technologies before or was this the first time?

LH: Surprisingly, once the decision was made in late 1986 to abandon the analog micromirror approach, it took us less than one year to model, design, and manufacture the first proof-of-concept chip, an array of 512 digital micromirrors.

However, the first prototype chip and projection system would take nearly five years of development time. Significant hurdles had to be overcome in the areas of DMD chip architecture, fabrication, packaging, and testing. On the system side of things, no one had ever designed a digital projection system based on DMDs. A large part of that development involved unique image algorithms and optics.

In May 1992, only a few months after the company formed a corporate-level venture project to commercialize the technology, a prototype 768 x 576 resolution DMD projection system was demonstrated.

Looking back on the whole experience, five years of development time doesn’t seem all that long, considering the unique challenges posed by this new technology and the fact that TI had no prior experience with commercial projection display technology.

- Log in or register to post comments