Inner Workings: Inside an Electrostatic Speaker

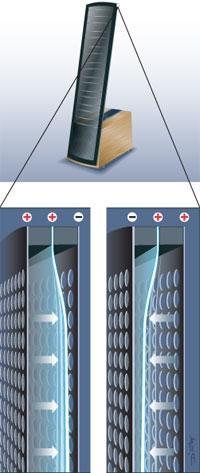

| The driver panel in an electrostatic speaker is composed of an electrically charged diaphragm placed between two metal screens. Changes in the strength and polarity of the electrical charge on the screens move the diaphragm back and forth, creating sound. |

All MartinLogan ESL transducers have three main components: an ultralight diaphragm (originally Mylar polyester but now a polyethylene film); a pair of rigid, perforated metal panels called stators; and nonconductive spacers called spars, which are strips placed across the stators to help increase panel stiffness while ensuring the diaphragm doesn't get too close to the stators. The diaphragm, which is impregnated with an electrically conductive material, is stretched tightly between the stators.

ESLs need to be plugged into a wall outlet so that a high amount of voltage - between 2,500 and 3,500 volts - can be sent to the diaphragm's surface, giving it a constant positive charge. A toroidal transformer changes power from an amplifier into high-voltage signals, which are sent to the stators in opposite polarity. Depending on the stators' charges - one is positive, the other negative - the diaphragm is pushed and pulled rapidly between them to create sound.

There are several advantages to this design. Because the diaphragm is so thin and light, it can respond very rapidly to changes in musical dynamics. And since it's driven uniformly over its entire surface, it operates across a wide frequency range, eliminating the need for woofer/tweeter crossovers (and the frequency-response and radiation-pattern irregularities they can cause) in the upper midrange or treble. Also, the dipole radiation tends to cancel sounds at the edges of the speakers, reducing side-wall reflections.

But the design also presents some formidable challenges. For instance, high voltages can cause arcing. Also, because ESLs have such large diaphragms they can be very directional - particularly in the high frequencies - with a narrow sweet spot. MartinLogan has addressed both issues with its Curvilinear Line Source panels, which are curved rather than flat, increasing horizontal dispersion. And the stators on the company's panels are coated with aerospace insulation that can handle high voltages without arcing.

If you've never listened to them, you owe it to yourself to audition some ESLs to see why many audiophiles worship at their altar. At the very least, you'll gain an appreciation of how different they are and of the engineering required to overcome their considerable design challenges.

Read the last Inner Workings Back to Homepage What's New on S&V

- Log in or register to post comments